Still a bit of work to do – mostly clean-up. They do not yet work perfectly, but they do work!

Almost there……

•August 20, 2009 • Leave a CommentKey Fabrication

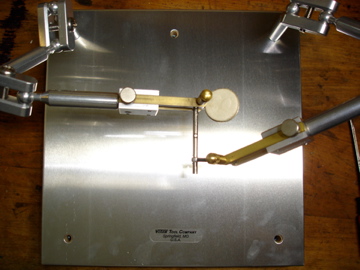

•August 16, 2009 • Leave a CommentPosted above is my latest attempt at building Ab and Db levers for a King Super 20 tenor saxophone. The mechanics of the left hand pinky table on a king saxophone work like no other – essentially backwards from the more standard version. I started this project months ago by getting my hands on a complete king, removing the keys and carefully taking pictures and measurements. The previous attempts at copying the original mechanisms have been colossal failures. When I obtained the soldering jig I began another attempt, but could not find any of the pictures nor measurements from the original keys.

Instead, I made the attempt from scratch. What you see above is an unfinished version of the key stack, rough and missing the Db table. The piece running parallel to the top of the picture is the bar that will attach the table to the hinge rod. Will need to replace the B roller.

So far, the primary change from King’s original configuration involves the return spring for the Ab lever. On the original design both the Ab and Db return springs were needle springs, and ran parallel to each other in close quarters. I removed the Ab spring, instead installing a flat spring in a different place. This freed up some space in the mechanism for the Db to work properly.

Components from raggedy old Conn and Yamaha cadavers have been used in this project.

I am not sure if this is the final build out or not, but I am positive that at long last this is a doable project.

New Tool Day!

•August 13, 2009 • Leave a CommentFor various reasons I have not bought a new tool in over two years. The last that I remember was a complete set of fancy screwdrivers from Ferree’s, right before I went to work for Holze Music. Holze, of course, went bankrupt. Several months later I attended the liquidation sale, and purchased nearly a complete shop worth of tools – but none of those were new. I say nearly because there are still a few gaps, mostly specialty tools that I have put off purchasing until the necessity arose. So, without any further ado, here it is!

Progress

•August 11, 2009 • Leave a CommentWhen I went through my second of four apprenticeships in this industry, I was trained by a kindly man that was young when the industry was, one Dr Lorin Richtmeyer in Denton, Tx. Dr Richtmeyer trained us to do everything with shellac. Just like great great great grand-pappy band man did. (I mean no disrespect, Dr. Richtmeyer was a great man, but many of his processes were rather dated.) Key corks, tenon corks, and pads, all were adhered by traditional shellac. With an alcohol lamp. I doubt anyone reading this realizes the awkwardness of heating shellac to the proper temperature so that it will adhere to a metal, wood, or plastic object, and then making it stick down on to cork – which in itself flammable – can be. And tho I occasionally wish for the simplicity of an alcohol lamp, I have friends in the industry that have been hospitalized from spilled burning alcohol.

So we learn to use more modern adhesives. By my third apprenticeship (with my friend Gary Dosset) I was introduced to contact cement. Contact cement, possibly first utilized in the 1960’s, found its’ way into the band instrument field. Safer. Slightly stinkier. But no flame needed- just time. Clean surfaces, sanding lightly and wiping with alchohal, apply glue (typicaly thinned with appropriate chemical,) wait for the glue to dry, then stick together.

More about shellac in another post.

Now, 20 years later, I may well be moving on. Welcome to better living though chemistry: 3m produces a “plastic to metal” adhesive that removes the “wait until dry” process. So far, the process is: lightly sand metal, clean surface, apply thin layer of adhesive to metal, stick pre cut material (slightly larger than surface) and press down. Set aside and wait 2-5 minutes. Razor blade off the excessive material and glue. It shaves (pun intended) much time off a PC job.

Key Fabrication

•August 9, 2009 • Leave a CommentThis is a key off of a Fox Bassoon. The hinge tube is ruined- it is bowed, and there is something stuck in it. It looks as if someone previously tried to drill it out, but instead drilled through the wall of the tube. I am going to unsolder the three pieces (the key cup, the lever, and the spring hook) and then solder them on to a new tube. If all goes well, I will not have to then have the key stripped and re-platted. I really hope all goes well…..

A hinge tube is the part of a key that a rod goes through so that the key can move up and down. Just like a door hinge. There are two ways that a key is held on, either with a rod that goes all the way through the hinge tube, or with a pivot screw (or pin, in a few obscure examples) that holds the key on either side. A good example of the same mechanism using both systems, in this case a low C/Eb mechanism, are a Bundy II saxophone and a Selmer Paris saxophone. The Bundy II used a hinge rod, which supports both keys. The Selmer Paris uses four separate pivot screws to accomplish the same.

Rock and Rollers. And Oil.

•August 9, 2009 • Leave a CommentI cannot tell you how many times I have struggled to remove a key roller. Every other mechanism on the instrument may be well oiled, but somehow the poor rollers are so very often neglected. Like any other steel that is exposed to oxygen, the rod that secures the roller rusts, sometimes so badly that the plastic roller seizes up. So next time you send you instrument in to your friendly neighborhood repair center for a PC job, ask them if they can spare a drop or two of oil for the roller.

Shown above is the right hand key set on a Fox bassoon. Note the two black pieces on the keys, those are rollers. They are utilized to eaze sliding your thumb on and off the mechanisms. Flutes, saxophones, and harmony clarinets use them.

Leaks in a saxophone

•August 9, 2009 • Leave a CommentThis is the lower F key on a selmer super action 80 tenor saxophone. A very leaky F key. Working in a dimly lit room, I put my Votaw leak light (essentialy a flourescent tube on a wire) inside the body and watch what the pads do when the keys are gently depressed. The single best explanation of the process I have ever read is on Curt Alterac’s site. In fact, all repair techs should read the articles on his site – quite possibly the most thought out explanations of what we do that is available. You can find his articles, along with all the products he peddles, at musicmedic.com

Awaiting pickup

•August 5, 2009 • Leave a CommentThis soldier fell in battle. Or, more accurately was knocked over by a trumpet player. Much damage resulted – pads were replaced, tone holes were dressed, keys were straightened, and dents were removed.

This is one of my favorite saxophones to hit the market in recent years. They play wonderfully, sound great, feel great, and are very well constructed. My client had some tuning issues with the top end of the instrument, I shaded some of the tone holes to lower the pitch.

Update: When the client picked up the horns he told me that the Selmer alto had never played as good as it does now. We made further alterations to the ton holes on the tenor, and got its’ pitch down to where he wanted it. Nothing quite as satisfying as a job well done.

Anger Management

•August 5, 2009 • Leave a CommentSelmer Super Action 80 Series II Disassembly

•August 3, 2009 • Leave a CommentA client came by this morning and left me his Selmer Super Action 80 tenor saxophone. He plays mostly down in Seabrook, on an outside deck right by the bay. Nothing spells bad news for a saxophone quite like humidity, especially right by the ocean. I am going to take it apart and clean the it, then lubricate and assemble it. The palm key pads and low Eb pad have accumulated enough wear and gunk that they need to be replaced, some of the key corks have failed or gone missing, and most of the open keys are leaking. He also wants the palm keys built up; they are too low for his hand.